Plasma Transferred Arc Welding (PTAW) is similar to Gas Tungsten Arc Welding (GTAW). It may be considered an evolved version of the GTAW process because it uses the plasma principle to bring you your desired results.

This welding procedure is used to deposit high-quality metallurgically fused materials onto surfaces. The goal of Plasma Transferred Arc Welding is to improve the surface properties of various equipment components and mechanical parts.

The Process

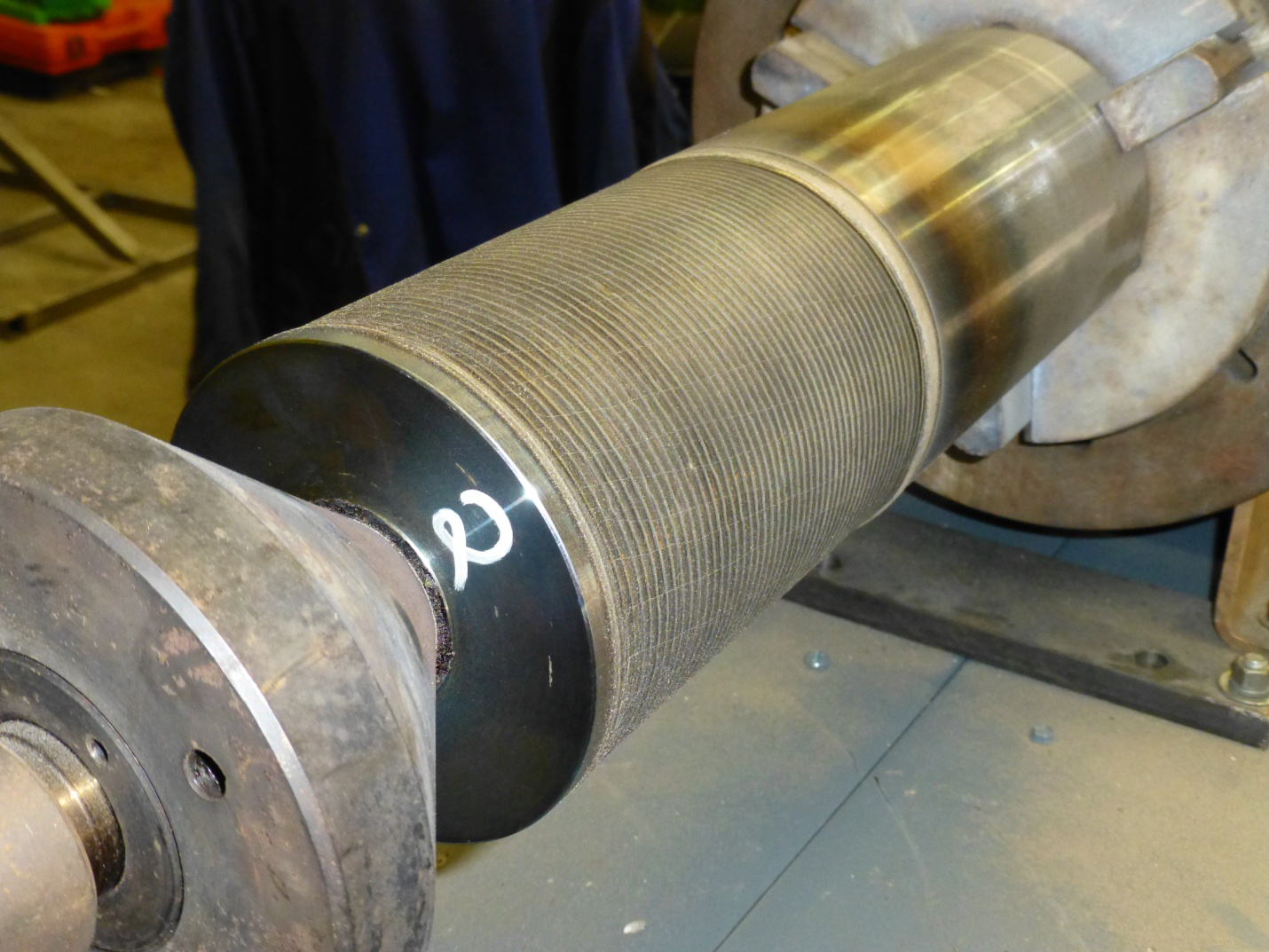

The Plasma Transferred Arc Welding process utilizes superalloy metal powders to offer hardfacing properties to mechanical parts. The process uses carbide composites, soft alloys, and materials of medium and high hardness to improve your mechanical capabilities. Some of the outcomes of Plasma Transferred Arc Welding are greater mechanical strength, resistance to wear and corrosion, and reduced downtimes for repair.

As a modification of the Gas Tungsten Arc Welding process, PTAW is a versatile procedure that uses a constricted, high-energy plasma arc to create a molten weld pool. The thermal process applies corrosion and wear resistance layers on metal surfaces. Unlike other processes, Plasma Transferred Arc Welding produces a metallurgically bonded overlay that has better properties in terms of corrosion and fusion.

The Applications

Plasma Transferred Arc Welding offers a host of benefits to experts in various industries. By offering wear resistance and high productivity, PTAW’s advanced technology can be utilized in numerous applications.

This procedure is vital in applications where extreme resistance to wear and damage is necessary, and highly-erosive conditions are common.

Some of the typical applications that use Plasma Transferred Arc Welding are:

- Cutting tools

- Mining and agricultural industry

- Accessories and molds in the glass industry

- Hydraulic cylinders

- Industrial-grade blades and knives

- Extrusion molds and rings

- Valves and screws

- Paper industry equipment

- Equipment for road building and tunneling

- Power generation and chemical industry accessories

The Benefits

The process of Plasma Transferred Arc Welding offers significant advantages to experts in various industries. Depending on the needs of your applications, PTAW may be the right choice for you.

Some of its advantages are:

- It produces alloy deposits that are resistant to corrosion and stronger than other processes

- It’s an economical alternative to preserving the integrity of mechanical parts and ensuring frequent repairs and replacements aren’t required

- The metallurgical homogeneity allows for standardized results each time; consistency of results is necessary for various industrial applications

- The amount of filler lost in PTAW is significantly less than Tungsten Inert Gas (TIG) and Metal Inert Gas (MIG) welding processes; this improves your ratio of price and quality

- The low dilution rates ensure that the PTAW process achieves quality results using less material

Are You Looking For Welding Experts In Wasilla, Alaska?

Take advantage of PlasmaTech’s advanced welding technology for your next project. We offer state-of-the-art technologies and high industry standards to bring you cutting edge Plasma Transferred Arc Welding and various other welding services.

From CNC Plasma Cutting and metal fabrication to general welding and hardfacing services, we’re one of Wasilla’s best.

Get in touch with our certified welders for more information!